-40%

Huacaya Alpaca Fiber Fine Grade 3 True Black Batt 5.8 oz .36 Lb Roving Spinning

$ 12.59

- Description

- Size Guide

Description

Description of This Product:You are buying: 5.8 OZ. (.36 LB.) OF GRADE 3 (FINE) FIBER, AS MULTIPLE, APPROX 20.5"L x 8"W BATTS.

The images show the 5.8 ounces of this fiber on a 15"x 20" cutting board, at normal fluff after lifting from the drum carder.

Preparation: This fiber has been:

- Carefully skirted as a raw fleece to remove, to the extent feasible, guard hairs, light colored hairs, non-blanket hairs, and large contaminants

- Washed to remove most oils and fine dirt particles

- Combed to remove most neps (fiber clumps), noils (very short fibers), and remaining debris. The very short-fiber fuzz that naturally arises in this type of fiber has been substantially removed with fine combing, leaving longer fibers suited to spinning strong yarn strand.

- Hand drawn from the combs and the hackle into sliver, orienting the fibers in parallel

- Drawn out to improve blending, and fed end first into a drum carder to better preserve parallel orientation

- Removed from the drum carder as batts

Use: These batts are ready to draw into roving for woolen or semi-worsted spinning with quite long fibers, to process with other fibers, to further comb and draw into a long fiber top for smooth worsted yarn or thread, to make a very strong felt, or to use in other ways. This length is not recommended for bird nesting, due to possible entanglement.

Color: Natural, undyed. This blanket cut of fleece, after skirting, is almost entirely of the natural true black color. Some light fibers remain that can yet be pulled out, but most have been removed throughout the several skirting and processing steps.

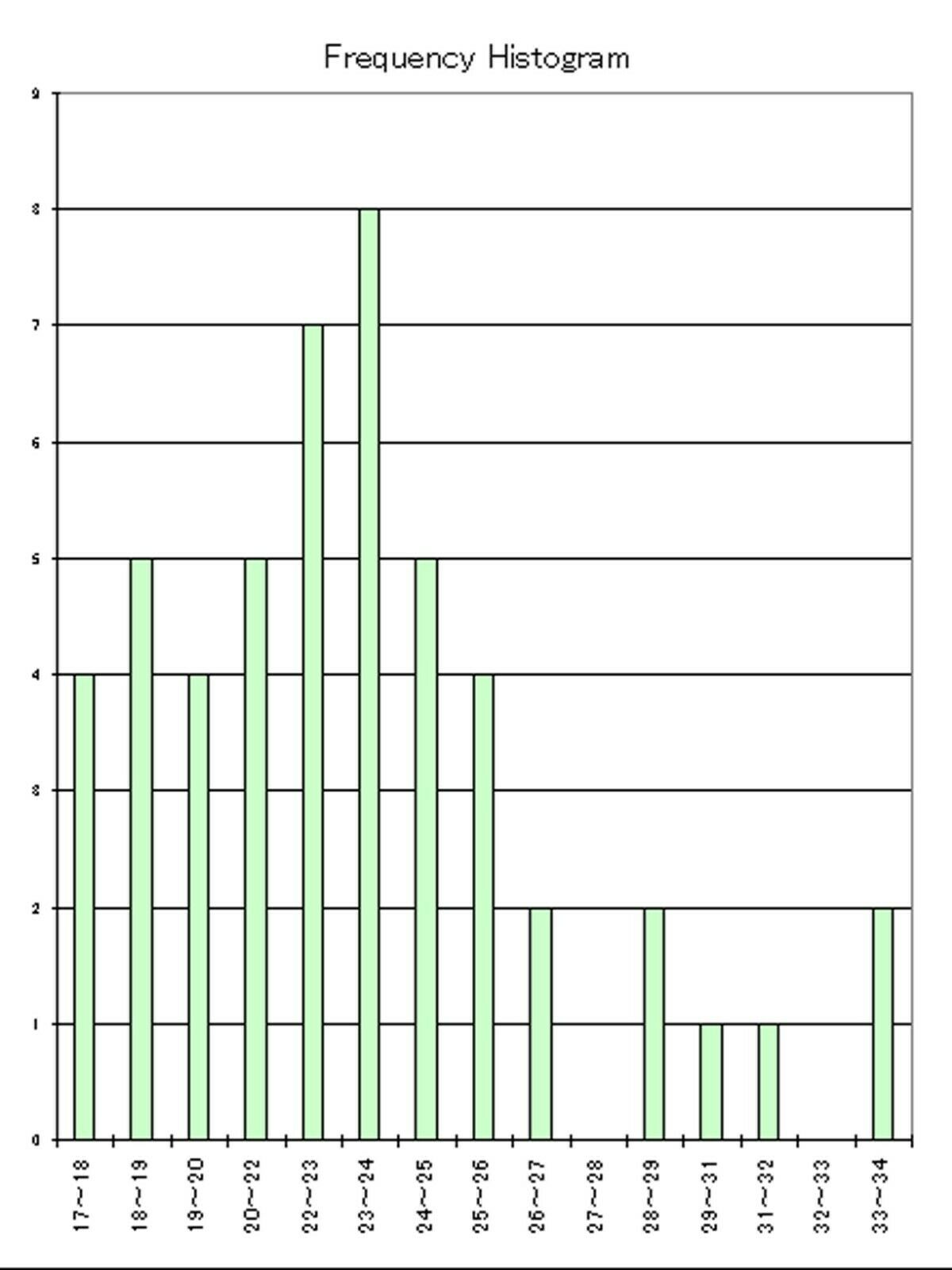

Grade: Predominant fiber length for these batts is approx 6", with a few fibers longer, up to about 9.5". As is normal, fibers of shorter length exist in descending quantity. Any below about 3" have been mostly removed in combing. Tested fiber diameter from the batts averages at about 23.0 microns, just into grade 2, super fine, but reducing this batch to grade 3, fine, seems more legitimate. The histogram image provided in this listing summarizes 50 random measurements, +/- 1 micron, from these batts.

Contaminants: Some flecks of loose vegetation.

More information about this fiber:

- Fleece#: 43720

- Fiber type: Peruvian Huacaya Alpaca

- Source: Amazing Grace Ranch, Elizabeth, CO

- Shear Area: Blanket

- Color (nearest standard approximation): True Black (500 TB)

- Animal Name: Ebony Joy (Joy)

- AOA Reg#: 30332348

- Animal Gender: Female

- Animal Birth Date: 8/7/2011

- Shear Date: 6/25/16

Some general information on the qualities, use, and processing of alpaca fiber:

Fleece Areas:

- Blanket (back from lower neck to tail): Best quality. Some animals have coarser guard hairs in the tips than others, and fiber diameter and qualities can vary by genetics, animal age, and annual environmental conditions.

- Neck and Belly: 2nd quality, somewhat coarser. Neck fiber is longer than belly fiber.

- Legs and tail: 3rd quality, coarsest, and rather short

Fiber diameter grades:

- Grade 0, Royal Alpaca - under 18 microns

- Grade 1, Ultra Fine/Baby - under 20 microns

- Grade 2, Super Fine - under 23 microns

- Grade 3, Fine - under 26 microns

- Grade 4, Medium, under 29 microns

- Grade 5, Intermediate, under 32 microns

- Grade 6, Robust, under 35 microns

- Grade 7, Coarse, over 35 microns

Staple Length:

In general, short fiber (more like 2-4 inches) yields fluffier (warmer) but weaker yarn. Yarn from long fiber (more like 5-7 inches) can be quite fluffy if loosely spun, or dense if more tightly spun, but with fewer tips exposed, this yarn is smoother and stronger.

Fiber less than 1.5" can be used to make felt, but is not a normal choice to make yarn.

Woolen and worsted: In making yarn, basic English types are "woolen" and "worsted". As a most basic description, woolen uses fiber that is often simply carded, is not made particularly parallel in alignment, and may contain substantial neps (small clumps) and noils (very short fiber lengths), producing a weaker, fluffier yarn. Worsted, meanwhile, uses fiber that is combed to pull out noils, neps, and contaminants, leaving longer fibers in a parallel alignment. These longer, parallel fibers move intact through the spinning process to yield smoother, firmer, and stronger worsted yarn. Handcrafted yarns commonly fall somewhere between these polar extremes, with a worsted purist diligently removing virtually all neps and noils and following through with a strict spinning procedure.